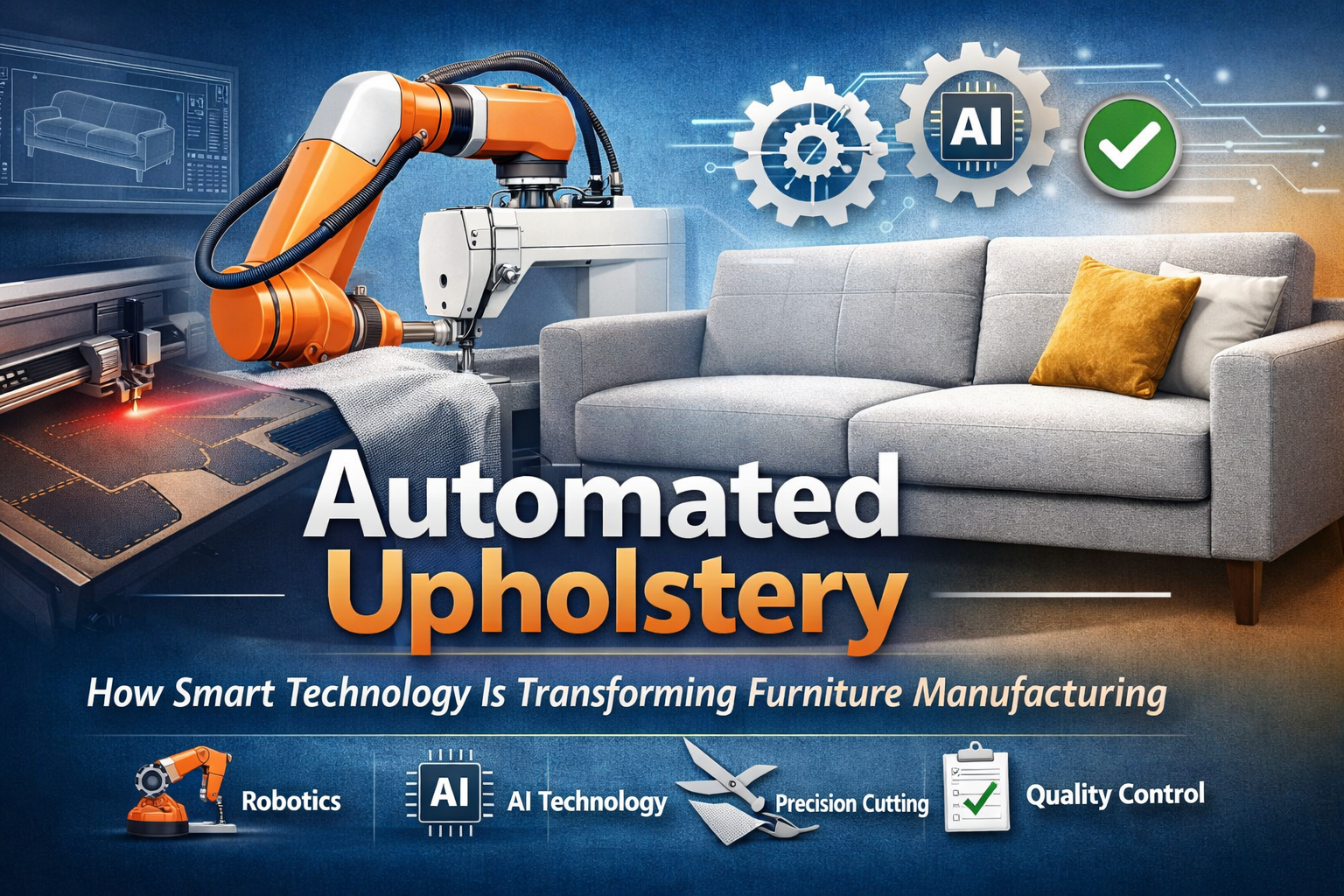

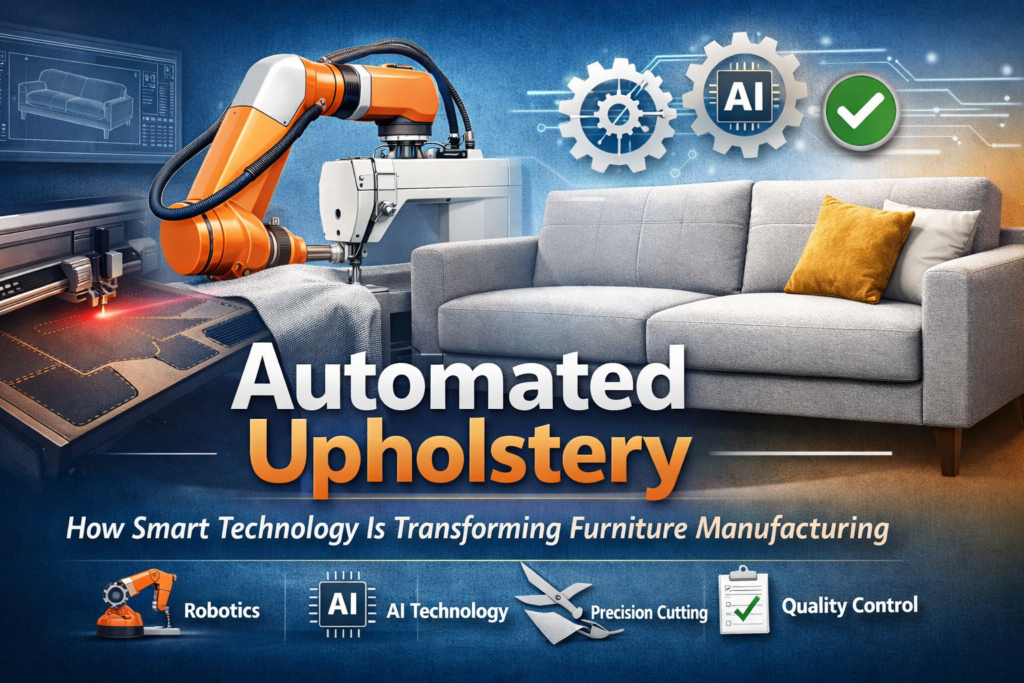

Automated Upholstery: How Smart Technology Is Transforming Furniture Manufacturing

Introduction

Upholstery has always been a craft rooted in skill, patience, and precision. From hand-cut fabrics to carefully stitched seams, traditional methods built the furniture we still admire today. But modern demand for speed, customization, and consistency has pushed the industry to evolve.

That evolution is now led by automated upholstery—a blend of robotics, digital design, and smart manufacturing that is redefining how sofas, chairs, and interior furnishings are made. What once took days of manual labor can now be completed in hours, often with less waste and higher accuracy.

In this article, you’ll learn what automated upholstery really means, how it works, why manufacturers are investing in it, and what it means for consumers and designers alike.

What Is Automated Upholstery?

Automated upholstery refers to the use of computer-controlled systems, robotics, and advanced machinery to perform tasks traditionally handled by skilled upholsterers. These systems can:

- Cut fabric and leather with laser or blade precision

- Sew seams using programmable patterns

- Apply padding and foam

- Stretch and staple materials onto frames

- Inspect finished pieces for defects

Rather than replacing craftsmanship entirely, automation supports it. Human designers still choose materials and finishes, while technicians oversee machines and handle final quality checks.

The result is a production process that blends efficiency with consistency, ideal for today’s fast-moving furniture market.

Why Upholstery Automation Is Growing So Fast

Furniture brands face increasing pressure from rising labor costs, supply chain disruptions, and customers who expect quicker delivery times. Automated upholstery helps solve several of these challenges at once.

Faster Production Cycles

Robotic cutters and sewing stations can operate continuously, often reducing lead times by 30–50%. This allows manufacturers to respond quickly to trends and seasonal demand.

Improved Accuracy and Quality

Digital pattern mapping ensures every piece of fabric is cut the same way. Automated stitching maintains uniform tension, which reduces puckering and uneven seams. Over large production runs, this consistency can dramatically reduce defects.

Less Material Waste

Advanced nesting software arranges pattern pieces to maximize fabric usage. Some factories report material savings of up to 10%, which lowers costs and supports sustainability goals.

Safer Working Conditions

Repetitive cutting and stapling can cause strain injuries. Automation shifts those tasks to machines, while employees move into monitoring, programming, and finishing roles.

How Automated Upholstery Works

Behind every automated line is a tightly integrated system of software and machinery.

Digital Design and Pattern Creation

Designers create furniture models using CAD software. Upholstery patterns are generated digitally, allowing precise adjustments for size, seam placement, and fabric stretch.

Once approved, those files are sent directly to cutting machines—eliminating manual measuring and marking.

Automated Cutting Systems

CNC cutters, laser tables, and water-jet machines slice through layers of fabric or leather at high speed. These systems handle complex curves with ease and maintain perfect alignment across multiple layers.

Robotic Sewing and Stitching

Programmable sewing machines follow digital stitch paths. Some advanced setups include robotic arms that move fabric panels into position, ensuring accuracy even with slippery or thick materials.

Assembly and Padding

Foam placement and adhesive application can be automated as well. Robots apply padding evenly to frames, preparing them for final fabric fitting.

Quality Control with Vision Systems

Cameras and sensors scan seams, surface tension, and alignment. If defects are detected, the system flags the piece for inspection before it reaches packaging.

Real-World Examples from the Furniture Industry

Several large furniture manufacturers in Europe and North America have already invested heavily in automated upholstery lines.

One sofa producer introduced robotic fabric cutters and reduced production time per unit from four hours to just over two. Their defect rate dropped by nearly 20% within the first year.

Another custom seating company adopted automated pattern nesting software. By optimizing fabric layouts, they saved thousands of yards of material annually—an improvement that directly boosted margins while reducing environmental impact.

Even smaller workshops are embracing partial automation. Table-mounted CNC cutters and programmable sewing machines allow boutique brands to compete with larger factories without sacrificing design flexibility.

Benefits for Consumers and Interior Designers

Automation doesn’t just help factories—it changes what buyers can expect.

More Customization at Scale

Because patterns are digital, changing dimensions, arm styles, or cushion depth is far easier than with paper templates. Customers can order made-to-measure pieces without long waits.

Shorter Delivery Times

Faster production means sofas and chairs reach showrooms—and homes—sooner. This is especially valuable for hospitality projects and commercial interiors with tight deadlines.

Consistent Fit and Finish

When every seam is stitched to the same tolerance, the finished product feels refined and reliable. That consistency builds brand trust.

Challenges and Limitations of Upholstery Automation

Despite its advantages, automated upholstery is not without hurdles.

High upfront investment is the biggest barrier. Robotic cutting tables, sewing stations, and integration software can cost hundreds of thousands of dollars.

Another concern is material variability. Natural leather hides vary in thickness and texture, making them harder for machines to process than synthetic fabrics. Many facilities still rely on skilled workers to handle premium materials.

Finally, training is essential. Operators must understand programming, calibration, and maintenance to keep systems running smoothly.

The Role of Skilled Craftspeople in an Automated Future

Automation doesn’t eliminate human expertise—it changes it.

Experienced upholsterers are increasingly involved in:

- Setting machine parameters

- Inspecting complex finishes

- Handling luxury or delicate materials

- Creating prototypes and one-off designs

Their craftsmanship ensures that mass-produced pieces still meet aesthetic and comfort standards. In many factories, the best results come from collaboration between artisans and engineers.

Sustainability and Environmental Impact

Sustainability has become a major selling point in furniture manufacturing, and automated upholstery supports that shift.

Precise cutting reduces textile waste. Energy-efficient machinery lowers power consumption compared to older systems. Digital workflows also reduce paper use and storage needs.

Some manufacturers now combine automation with recycled fabrics and water-based adhesives, creating greener production lines that appeal to eco-conscious buyers.

The Future of Automated Upholstery

As artificial intelligence and robotics advance, upholstery automation will likely become even more adaptive.

Future systems may:

- Adjust cutting patterns automatically based on fabric stretch

- Use AI to predict defects before they happen

- Enable real-time customization for online furniture configurators

- Integrate fully with smart factories and inventory systems

This shift could make high-quality furniture more accessible while keeping production flexible and responsive.

Frequently Asked Questions

What is automated upholstery in furniture manufacturing?

Automated upholstery uses robotics, digital design software, and CNC machinery to cut, sew, and assemble upholstered furniture with minimal manual handling.

Does automation reduce furniture quality?

In most cases, it improves consistency and accuracy. Skilled workers still oversee finishing and inspections, ensuring high standards are maintained.

Is automated upholstery only for large factories?

No. Smaller workshops increasingly adopt partial automation, such as CNC cutters or programmable sewing machines, to boost efficiency.

Can machines handle leather and specialty fabrics?

Yes, but natural materials can be challenging. Many factories combine automation with human expertise for premium upholstery.

Is automated upholstery more sustainable?

It often is. Reduced waste, optimized fabric use, and energy-efficient systems contribute to greener manufacturing processes.

Conclusion: Why Automated Upholstery Matters Now

Automated upholstery is reshaping the furniture industry from the factory floor to the living room. By blending robotics with skilled craftsmanship, manufacturers achieve faster production, better consistency, and greater design freedom.

For consumers, that means more customization, shorter wait times, and dependable quality. For businesses, it offers a way to stay competitive in a demanding global market.

If you’re involved in furniture design, manufacturing, or sourcing, now is the time to explore how automated upholstery can elevate your production strategy and future-proof your brand.